Precision. Performance. Perfection.

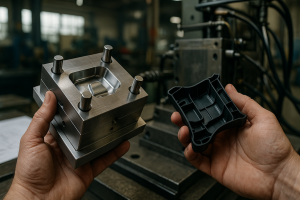

Our Injection Molding Capabilities

The other two companies had developed a wide range of internal and external, hard and soft quality measures. These companies used managers as well as customers to measure both tangible and intangible aspects of service. Internal measures were used to corroborate the perceptual measures drawn from customers and, conversely, the external measures were used to support service design and the setting of internal quality targets.

We offer end-to-end plastic injection molding services, including:

Industries We Serve

Video Presentation

Discover how Shiv Sagar Enterprise transforms ideas into precision-engineered plastic components through advanced injection molding. With state-of-the-art machinery and expert craftsmanship, we deliver quality, consistency, and scalability.

Trusted by industries across India and beyond for over 25 years.

Why Choose Shiv Sagar Enterprise?

At Shiv Sagar Enterprise, we combine decades of expertise with cutting-edge technology to deliver precision-molded plastic parts.

Our team is committed to quality, innovation, and client satisfaction across every project.

We operate from a modern facility in Ankleshwar, Gujarat, equipped for scalable production.

Trusted by both Indian and international clients, we ensure timely delivery and flawless execution.

Partner with us for reliable, cost-effective, and customized injection molding solutions.

Read Blogs

To meet its contractual obligations with its customers while also maintaining sustainable margins, a global industrial company needed to improve its equipment availability and reliability and also decrease its maintenance costs. The company identified advanced analytics solutions, specifically machine learning and predictive techniques, as a means to achieve this critical objective.

General Ask

Let’s face it, having to deal with problems can really suck, making you feel paralysed and out of control. Whatever the scale of your issues, there are steps you can take to feel more in control. And while you might not always make the right choice, you can learn how to feel comfortable with the decisions you make.

Features

Finding information on industries will require reviewing reports from multiple sources in order to get a complete picture of the industry. Key characteristics of the industry include geographic scope of the industry, the boundaries of the industry, and the dominant economic characteristics of the industry.