In today’s competitive manufacturing landscape, standard components often fall short when it comes to unique design requirements, demanding environments, or industry-specific compliance. That’s where Shiv Sagar Enterprise shines—offering custom plastic, silicone, and rubber moulding solutions that help our clients outpace their competition.

Why Customization Matters

Off-the-shelf parts might seem convenient, but they rarely align perfectly with an OEM’s exact needs. Whether it’s a unique geometry, specific material property, or precise fit and function, tailored components:

- Reduce unnecessary tolerances

- Improve product performance

- Streamline assembly processes

- Ensure better compliance with regulatory and safety norms

Our Approach to Custom Moulding

At Shiv Sagar Enterprise, customization doesn’t mean complexity. Our process is built for speed, precision, and collaboration:

Requirement Mapping

We start by understanding the client’s product design, stress/load points, and performance goals.Material Consultation

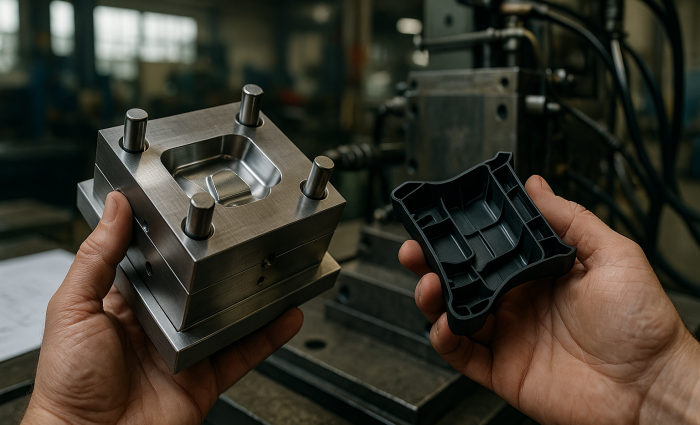

Choosing the right polymer or elastomer is critical. We guide clients through material properties like thermal resistance, flexibility, and wear durability.Rapid Tooling & Prototyping

Our in-house toolroom and 3D CAD capabilities allow us to quickly develop custom moulds and prototypes for review and testing.Precision Manufacturing

Using automated injection moulding machines and 5S-driven shopfloor management, we deliver consistent quality at scale.Feedback Loop & Refinement

We partner closely with clients to tweak and refine designs—turning one-time orders into long-term partnerships.

Why Precision Matters in Injection Moulding

Precision is not just about dimensional accuracy — it’s about performance, safety, efficiency, and durability of the final product. Here’s why precision is at the core of everything we do at Shiv Sagar Enterprise:

1. Fit and Functionality

A plastic component that is just 0.2 mm off-spec may not fit or function as intended, especially in critical assemblies like motor housings, pump impellers, or conveyor guides.

2. Reducing Downtime and Rework

Precision moulding means fewer defects, less rework, and less downtime on the assembly line — saving time and money for our clients.

3. Enhancing Product Life

Well-moulded parts with consistent wall thickness and stress distribution last longer and perform better under pressure, heat, or mechanical load.

4. Safety and Compliance

Industries like food processing and chemical manufacturing demand tight tolerance, food-grade, or chemical-resistant components — and precision ensures we meet those regulatory and operational standards.

Industries We Serve with Custom Solutions

- Automotive: Custom seals, grommets, and dashboard components

- Dairy & F&B: FDA-compliant silicone and rubber parts

- Electronics: Precision-fit housings and connectors

- Industrial Equipment: High-performance bushings, caps, and insulators

Real Impact: Custom vs. Standard

One of our clients in the motor manufacturing industry was facing recurring failures using generic rubber gaskets. After switching to a custom-formulated rubber compound and optimized mould geometry, downtime dropped by 40%, and part life nearly doubled.

Final Word: Why Custom is the Future

In a world where differentiation is key, customized parts are no longer a luxury—they’re a strategic advantage. Shiv Sagar Enterprise empowers businesses with high-performance, tailor-made components that boost reliability, compliance, and speed to market.

Looking for a moulding partner who thinks beyond the standard? Let’s build it your way.