In the world of industrial manufacturing, we often focus on large machines, metal components, and advanced electronics. But behind the scenes, it’s often the smallest parts — made of rubber or silicone — that ensure the smooth operation of entire systems. At Shiv Sagar Enterprise, we’ve seen how these “unsung heroes” play a crucial role in industries ranging from electric motors and pumps to dairy equipment and chemical processing units.

This blog shines a spotlight on the importance, performance, and versatility of rubber moulded components, especially silicone rubber, and why manufacturers across India and beyond rely on them for mission-critical applications.

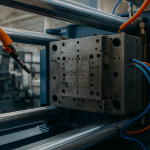

What Are Rubber Moulded Parts?

Rubber moulded parts are components manufactured using compression, transfer, or injection moulding methods where raw rubber is shaped into precise forms using heat and pressure.

At Shiv Sagar Enterprise, we specialize in moulding a wide range of rubber types, including:

- Silicone Rubber (for high-temperature, food-grade, or chemical applications)

- Nitrile Rubber (NBR) (for oil and fuel resistance)

- EPDM (for weather and ozone resistance)

- Natural & Neoprene Rubber (for general-purpose sealing and vibration dampening)

Why Are These Parts So Critical?

Even though they’re often small and overlooked, rubber parts perform vital functions in machinery and equipment:

1.Sealing

Rubber O-rings, gaskets, and seals prevent leakage of liquids, gases, or dust — critical in pumps, dairy lines, and chemical vessels.

2.Vibration and Shock Absorption

Rubber buffers, bushings, and mounts absorb vibration and reduce noise in electric motors, conveyors, and compressors.

3.Temperature and Chemical Resistance

Silicone rubber can handle extreme temperatures (-60°C to 230°C) and is resistant to many chemicals — perfect for food-grade and lab environments.

4. Flexibility and Compression

Rubber maintains flexibility under pressure, enabling repeated compression and release without damage — ideal for dynamic systems.

Industrial Use Cases: Real Applications of Shiv Sagar’s Rubber Parts

1. Electric Motors (AC/DC)

- Rubber grommets, insulators, and vibration mounts

- Protect wiring and reduce wear from mechanical motion

2. Pump Systems

- Rubber impellers and seals that maintain hydraulic pressure

- Nitrile rubber used for oil and chemical resistance

3. Dairy and Food Processing

- Food-grade silicone rubber parts used in milk tanks, valves, and pipelines

- Hygienic, non-toxic, and resistant to temperature fluctuations

4. Chemical Industry

- EPDM and Silicone seals in high-acid, high-alkali environments

- Withstand corrosion and extreme pH without degradation

5. Conveyor and Automation Systems

- Rubberized rollers, shock pads, and stoppers for smooth material flow

- Extend equipment life and reduce breakdowns

Why Silicone Rubber Deserves Special Attention

Silicone rubber stands out for its versatility and premium performance. We often recommend it when:

- Food-grade certification is needed (FDA compliant)

- Equipment faces high or low temperatures

- Non-reactive material is needed in medical or chemical processing

It’s more expensive than standard rubber — but when reliability is key, silicone is the smart long-term investment.

How We Ensure Quality at Shiv Sagar Enterprise

Quality is non-negotiable when it comes to moulded parts. We follow rigorous practices to ensure:

- ✔ Precise mould cavity design to minimize flash or deformity

- ✔ Material compatibility analysis for the end-use environment

- ✔ Batch testing for tensile strength, compression set, and chemical resistance

- ✔ Full traceability of raw materials and processes

Our manufacturing setup in Ahmedabad and Ankleshwar enables a daily output of 5,000+ rubber moulded parts, meeting urgent orders without compromising on quality.

🚀 Growing Demand: Why Rubber Parts Are Gaining Importance

As industries move toward automation, modular design, and lightweighting, rubber components are becoming more important than ever:

- They're lighter than metal alternatives

- Enable faster assembly

- Offer maintenance-free longevity

From Indian OEMs to international buyers, more companies are recognizing the strategic value of high-quality rubber parts in ensuring performance and durability.

🏁 Conclusion

In the grand scheme of manufacturing, silicone and rubber parts might seem small — but they are indispensable. They quietly protect, seal, cushion, and insulate our machines and systems. At Shiv Sagar Enterprise, we don’t see these parts as accessories — we see them as vital enablers of industrial performance.

Whether you’re building a new product or maintaining existing equipment, don’t underestimate the power of a precision-moulded rubber part. Partner with us for reliable, customized rubber solutions that support your success — one component at a time.

📩 Contact us today to discuss your rubber moulding needs.