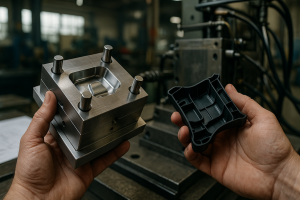

High-Strength Insert Moulding Solutions for Complex Applications

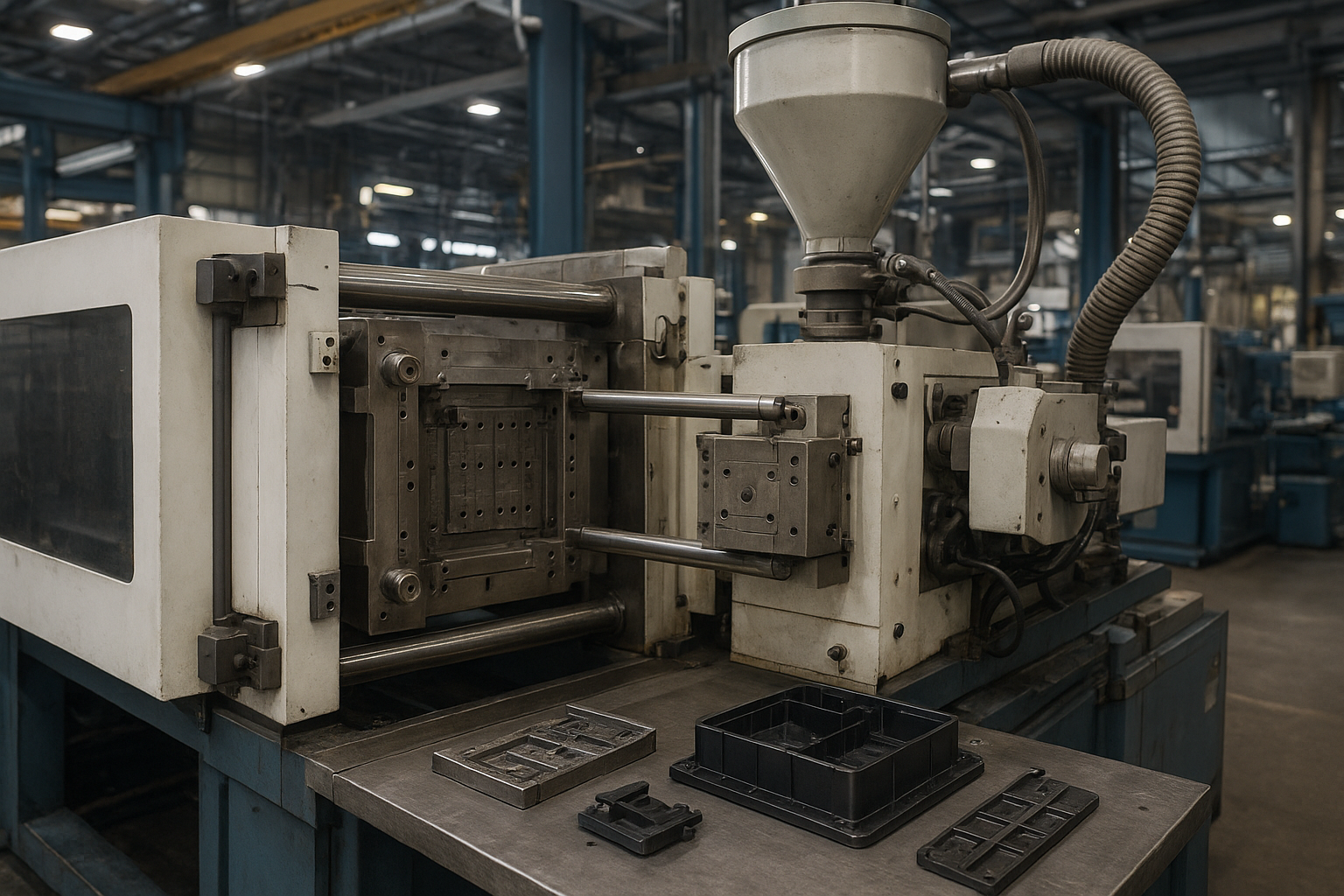

Insert moulding at Shiv Sagar Enterprise combines plastic with metal or other components to create strong, reliable, and integrated parts. This process reduces assembly time, enhances durability, and ensures precision for even the most complex designs—making it ideal for industries that demand both strength and efficiency.

Our Insert Moulding Services Include

Gazolin Services deliver a comprehensive portfolio of knowledge-based products and services to keep you ahead of the latest industry dynamics and technological changes. Our analysts sift through the clamor of market hype to deliver clear, concise, supplier-neutral summaries of key trends and technologies.

Video Presentation

At Shiv Sagar Enterprise, our insert moulding solutions combine plastic with metal and other components to create stronger, more reliable products. With advanced technology and precision engineering, we deliver durable parts, reduced assembly time, and cost-efficient results for industries worldwide.

Why Choose Shiv Sagar for Insert Moulding?

To ensure that the learning continued to provide ongoing value, we supplemented the workshop with an Industrial Predictive Analytics and Machine Learning Planning Guide. This guide provided baseline information about the industrial analytics market, vendor profiles, and recommendations for considering analytics projects.

News, Tips & More

General Ask

At Shiv Sagar Enterprise, our insert moulding solutions combine innovation, technology, and craftsmanship to deliver products that are stronger, more reliable, and tailored to your industry needs.

Features

Finding information on industries will require reviewing reports from multiple sources in order to get a complete picture of the industry. Key characteristics of the industry include geographic scope of the industry, the boundaries of the industry, and the dominant economic characteristics of the industry.